Supply Chain & logistics

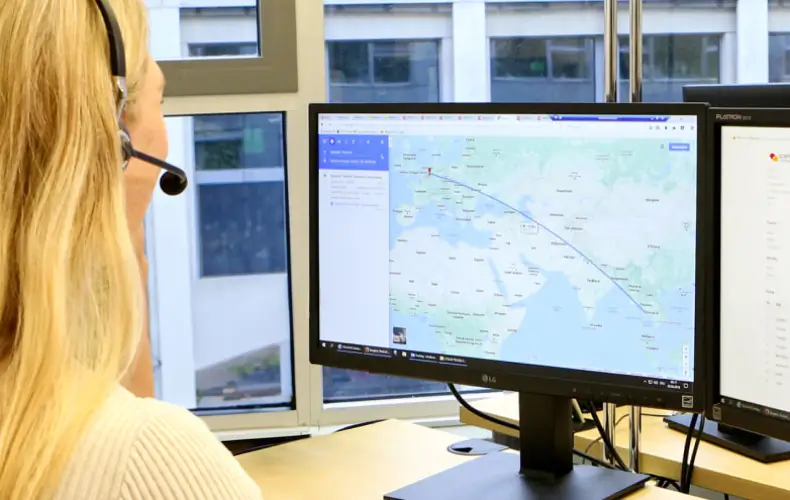

Safely underway: our cell transport

Cellex manufactures high-quality cell products for you and supports you in the development and use of cell therapeutics. We design and monitor the entire manufacturing process – from cell harvesting to further processing and delivery. In all working steps we put great value on flexibility, efficiency and productivity and coordinate closely with our global as well as national logistics partners along the entire supply chain.

Central coordination through Cellex Manufacturing Transports and Logistics (CMT) allows for fast and frictionless process sequences. Since 2014 we realized the cell transport of approximately 24,000 cell therapy products from various areas of application successfully to our national and international customers. We coordinate the organisation of the supply chain individually to your requirements. An intensive knowledge exchange with our logistics partners ensures safety during the entire process.

Contact us for your cell transport!

Coordination: an overview of our services

We take over product labelling for larger, regular projects, e.g. monitoring clinical trials from the donation to the study drug, as well as for smaller, one-time or occasional orders.

- Creation and delivery of documents and labels tailored individually to the requirement and additional materials for clinics and partners

- Creation of documentation and labelling for the manufacturing sector

- Consultation in the planning of product labels as well as additional labels in the GxP environment (design and material)

- Creation of labels (and label templates) using validated label software Management of label templates (with documentation and versioning)

In the process, we take into account:

- Requirements from public authorities (district government, Paul-Ehrlich-Institut)

- Requirements of the German Medicines Act (AMG) and the German Ordinance on the Production of Pharmaceuticals and Active Substances (AMWHV) and, if applicable, other local laws

- EU regulations

- GMP guidelines

- FACT-JACIE standards

In addition to the review of batch documentation in the GMP sector, our service includes the approval of intermediates and the EU approval of study drugs and medicinal products. The approval documentation is carried out in accordance with Good Documentation Practice (GDocP).

In cooperation with our qualified service providers, we take over the electronic and manual archiving of the batch and process documentation according to data protection law. The storage time is based on the requirements of the German Medicines Act (AMG).

The Cellex software delivery team ensures optimal digital control along the supply chain. We develop software solutions for the production, documentation and storage of cellular products and the coordination of various processes and digital transport tracking. As the product owner, we are responsible for the development process from the initial requirements to the implementation of the software solution. With regular reviews, we guarantee the GxP compliance of our software solution over the entire lifecycle.

We have already successfully carried out over 40,000 cell transport orders. To meet the special requirements for the transport of pharmaceutical and biotechnology products, we cooperate closely with selected logistics partners.

We take responsibility for:

- the proper handling of all matters related to customs during import and export

- supplier and service provider management

- quality management and compliance with GDP/GxP guidelines

- 24/7 tracking of all shipments – including inspection at the central interfaces

- emergency management

- validation of the transport process before implementation

We guarantee safe, efficient and fast processes:

- status as an Authorised Economic Operator (AEO) with Economic Operators Registration and Identification number (EORI)

- status as an officially recognised known consignor through air freight

- experience with registration for simplified declaration (vZA)

- observance of the chain of identity

To optimise supply chains and to ensure the greatest possible process efficiency, we rely on a complete preventive quality management system that allows all participants to react to unforeseen situations quickly and flexibly.

For this, we rely on the continuous training of our employees and the regular monitoring of processes through internal meetings, audits and by the competent authorities.

In terms of a holistic quality management system, we also offer you:

- qualification of materials

- transport validation

- deviation management

- change control management

- supplier qualification when purchasing materials and services

- risk management IT system validation

We take responsibility for:

- the proper handling of all matters related to customs during import and export

- supplier and service provider management

- quality management and compliance with GDP/GxP guidelines

- 24/7 tracking of all shipments – including inspection at the central interfaces

- emergency management

- validation of the transport process before implementation

We guarantee safe, efficient and fast processes:

- status as an Authorised Economic Operator (AEO) with Economic Operators Registration and Identification number (EORI)

- status as an officially recognised known consignor through air freight

- experience with registration for simplified declaration (vZA)

- observance of the chain of identity

Safe transport at any temperature:

Our cell transport solutions are always individually tailored to the product requirements: In addition to various validated transport options, we offer the best fitting cooling method for every temperature range. To guarantee the quality of cell products throughout cell transport, the temperature is recorded at all times using a calibrated logger.

Every day we perform national and internal blood-sample shipments without a cooling system. We are able to minimise the risk of delays through proactive monitoring.

We organise shipments worldwide with controlled room temperature or cooling.

The temperature range required in each case is kept constant for up to 72 hours using qualified materials – independent of the ambient temperature.

The cell transports are carried out accompanied by trained on-board couriers or unaccompanied in a secure freight environment.

Transport at -80°C guarantees that cells, samples or materials live longer. Special, qualified and reusable transport boxes of different sizes are used for these shipments.

For shipments of cryopreserved products, we use qualified Liquid Nitrogen (LN2) Dry Shipper. The transport containers absorb liquid nitrogen and keep the internal temperature between -130°C and -196°C. As they can guarantee a stable temperature over a longer period of time, LN2 Dry Shippers are optimal for worldwide deliveries.